Well, this is it. Final Assembly - Part II. After this post the Citation I rebuild project will be complete. That won't be the end of my Citation audio posts. But this post should do it for the rebuild.

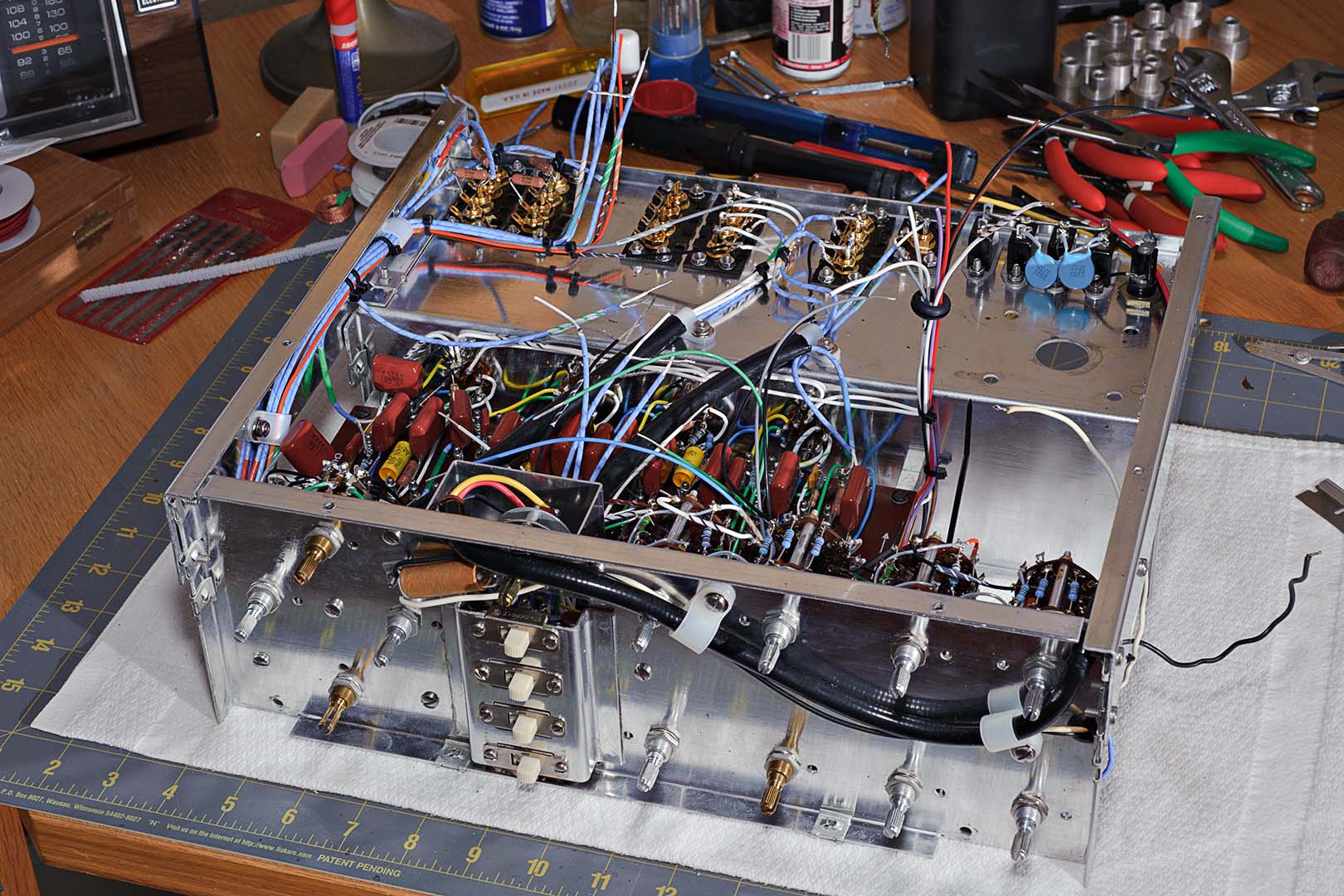

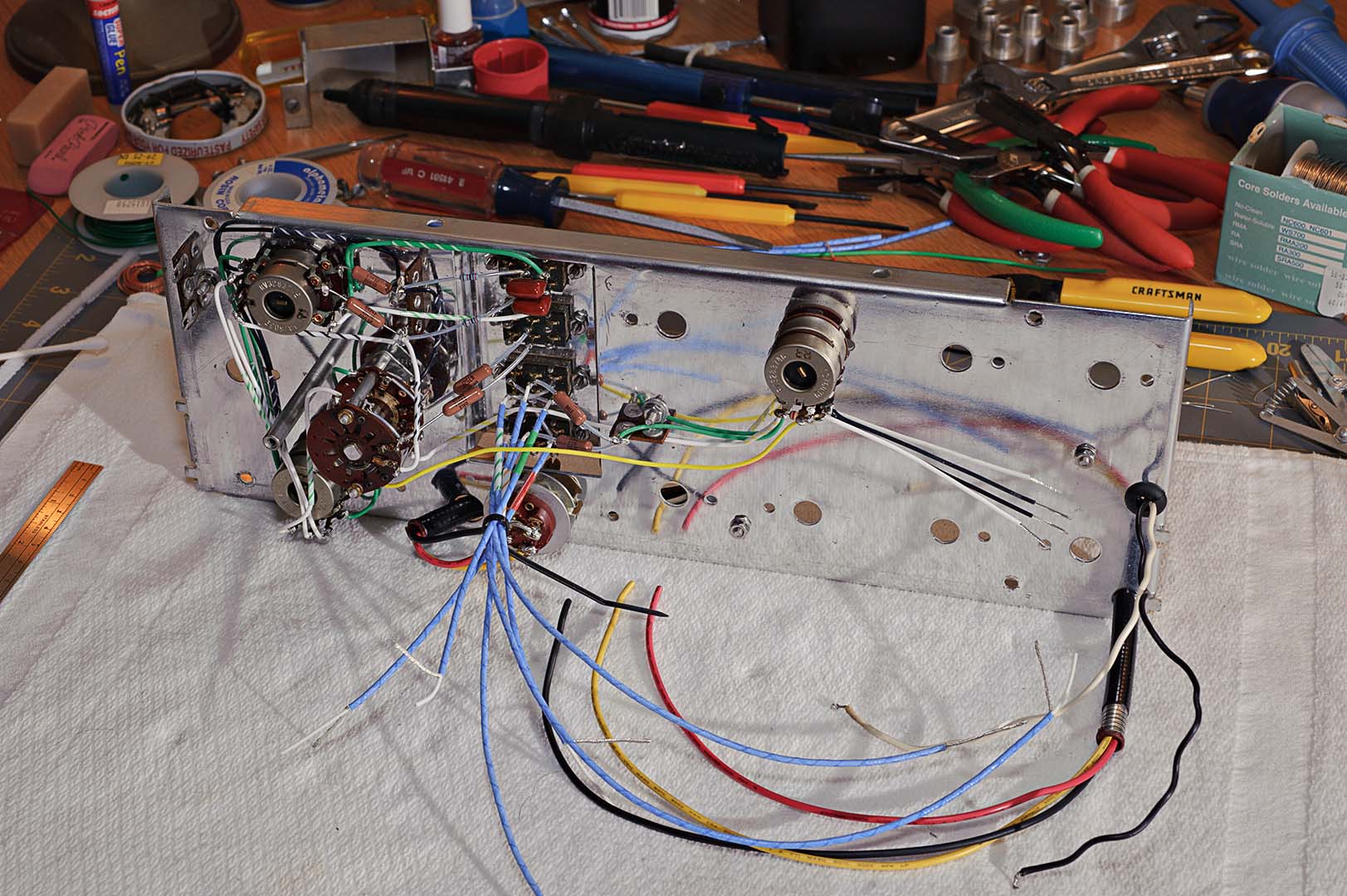

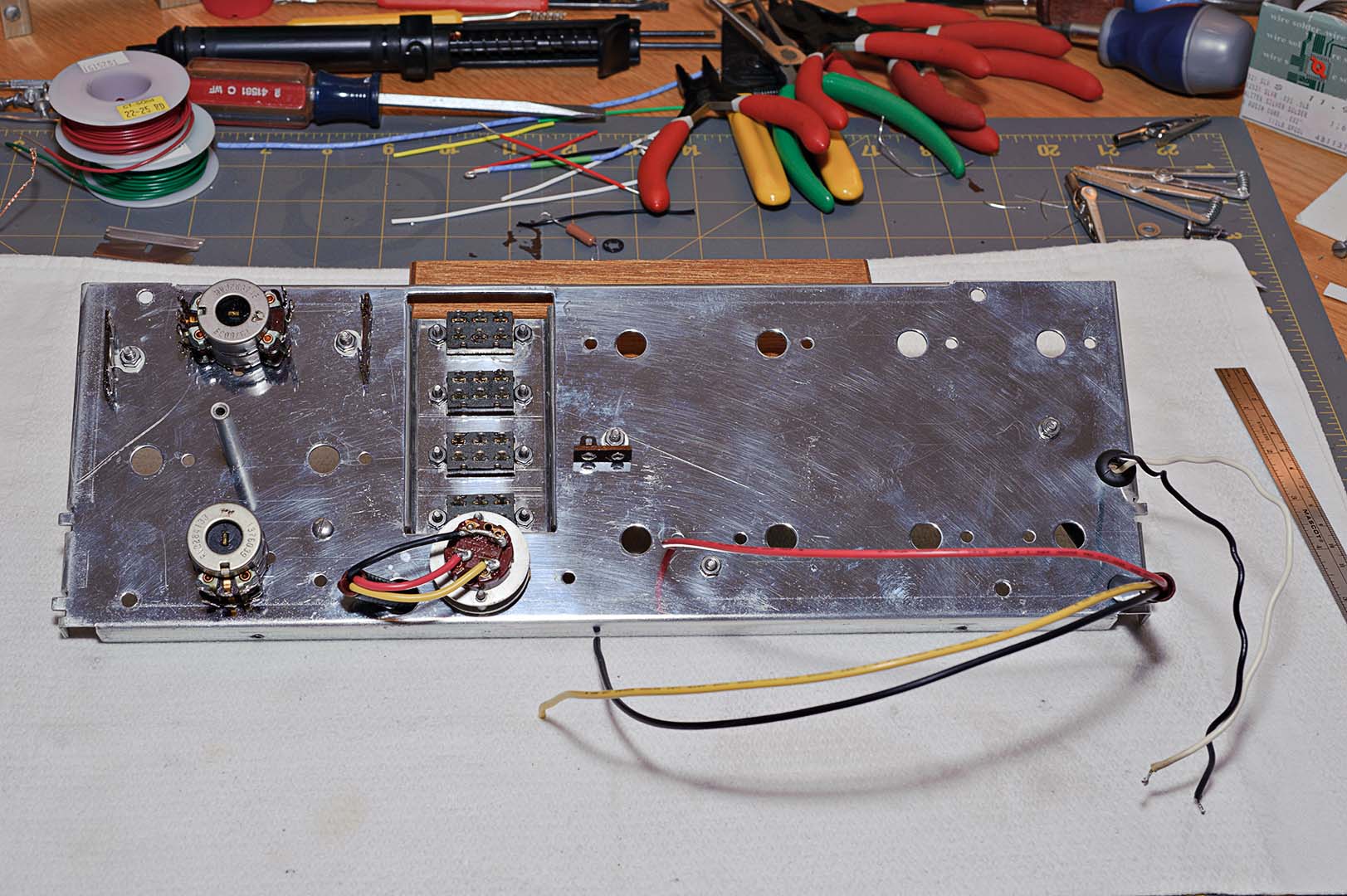

The last phase of the Citation assembly is to attach the power supply assembly to the main chassis and then attach all the wires. As I've said for the last few posts now, there's not much to it. Simply follow the instructions in the manual step by step. The power transformer is attached and the transformer wires are separated into three groups and routed as indicated in the manual. The bundle of wires from the main chassis is routed through the grommet on the power supply bracket and the bracket is then attached to the chassis using the appropriate washers and nuts. The following photo shows how the underside of the unit will look after these steps are completed.

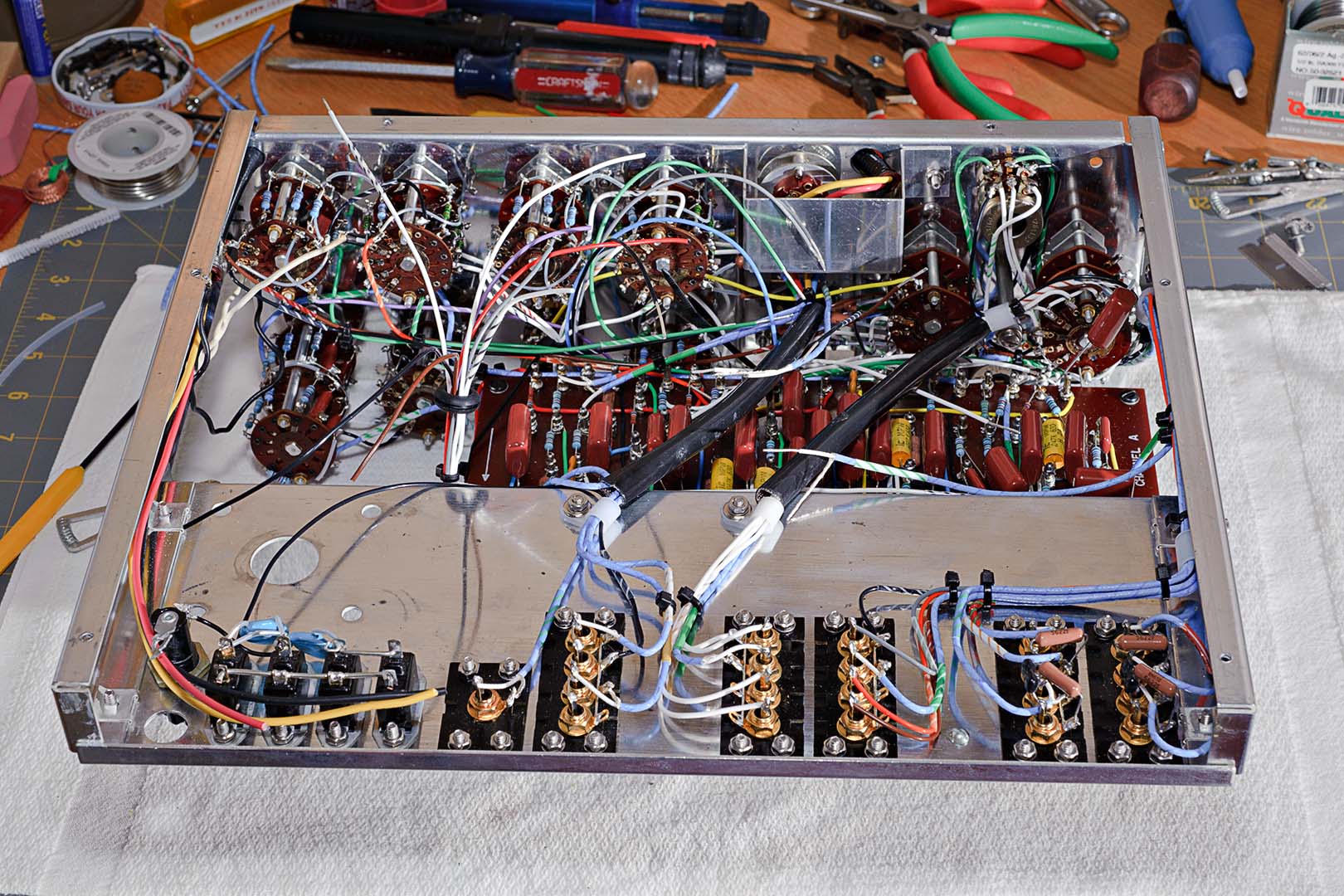

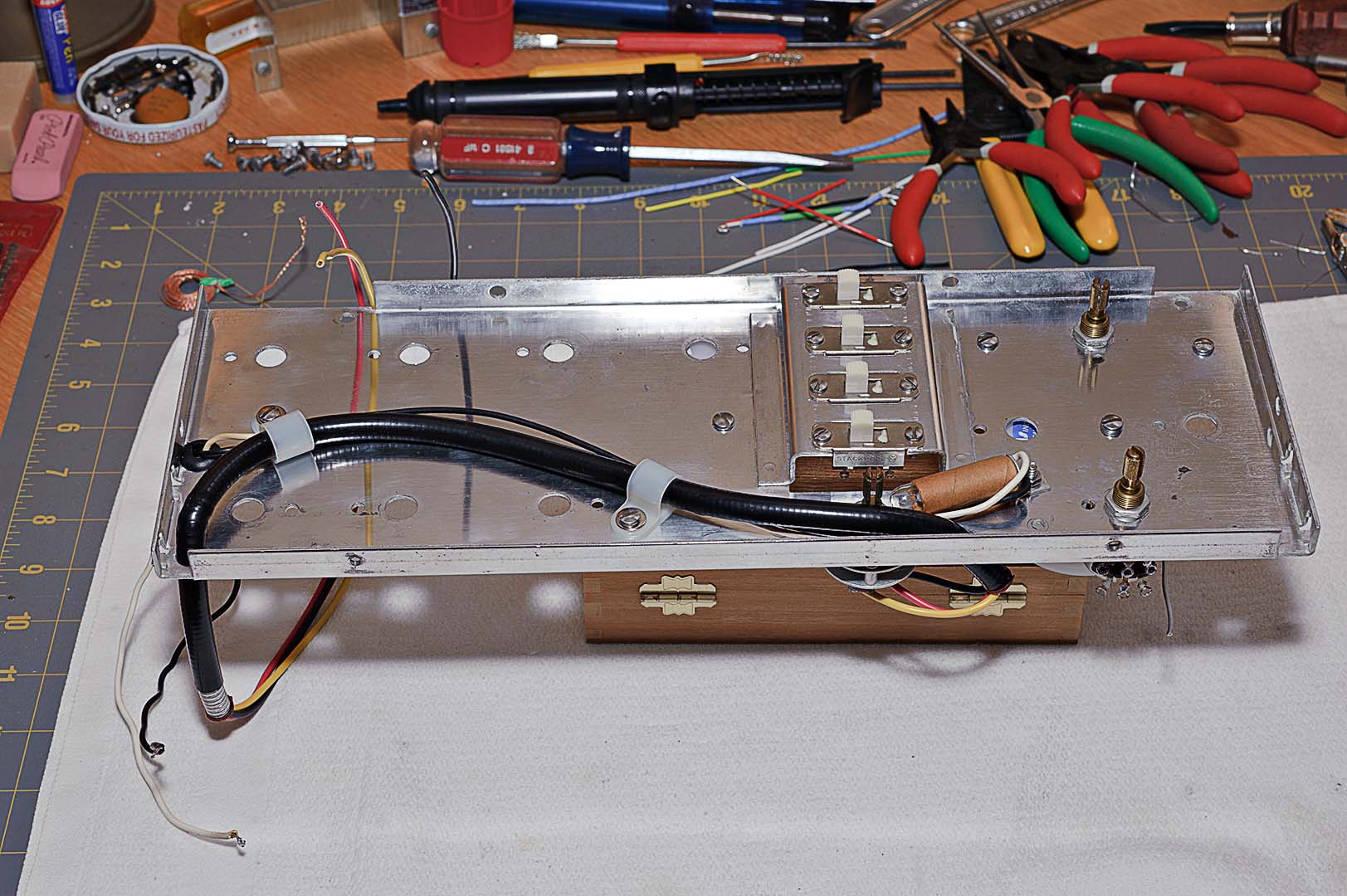

All of the loose wires shown in the above photo now need to be soldered to their attachment points. Again simply follow the instructions for dressing the wires and solder them to their final destination. Lastly, the power cord is inserted into the back deck of the chassis and the white and black wires are connected to the indicated points. That is it for the wiring. You are done! The underside around the power supply bracket after all the wiring is complete is shown in the following two photos. You can see the two capacitors just to the left of the choke (or above, depending on the photo) have been dressed in an upright position as opposed to lying flat as they were before final assembly. I am satisfied with the neatness of the assembly.

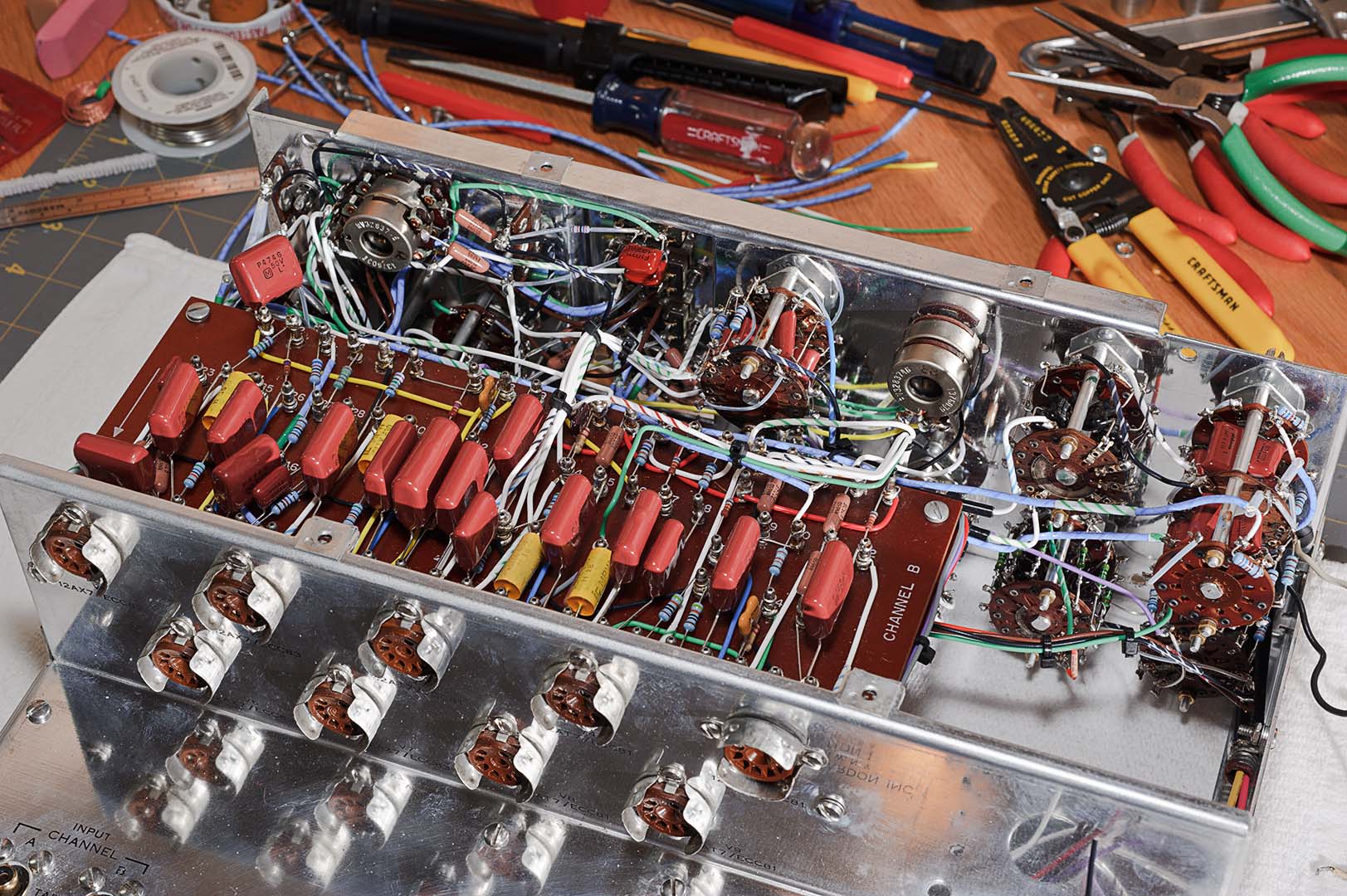

The following two photos simply show the top of the unit after all the wiring is complete. You can see that I have installed the tubes before I have completed mounting all the final hardware (the front plates, knobs, bottom plate, top cover). The tubes were installed so that the unit could be tested for correct resistances and voltages as specified in the Citation pictorial diagrams before mounting all the remaining hardware.

The three escutcheon front plates are loosely connected to the back plate. The hexagonal spacers are attached and all of the plates are tightened. The clear plastic power switch is installed next. Finally, the front plate assembly is mounted to the chassis. It's upside down, but the unit with the front plate installed is shown in the following photo.

Lastly, the knobs are installed onto the switch shafts. The only thing of note on the knob installation is getting the milled indicator line on the knob pointing to the correct position. For most of the switches that have discrete settings, like the function switch or the rolloff switch this is a simple matter. For the loudness and balance pots you'll have to decide for yourself. I installed my knobs so that they point at 12:00 when the pot is at the midpoint of its travel. The following two photos show the completed Citation I pre-amp from the front and rear.

The second photo reveals that I have already installed the bottom plate and the rear cover. In fact, there are a number of things to do before installing these two pieces. There are a few steps in the assembly manual still to be completed before closing the unit up. These involve powering the unit on, checking voltages and resistances, etc.

When I first powered my unit on the fuse blew. Oh no! I thought. All that work! I don't know if the added capacitance in the power supply causes a greater initial current draw when the unit is powered on. In any event, I decided to give it another try with a new fuse. This time I installed a slo-blow fuse. This was based on a similar experience I had with my Citation II amplifiers after they were rebuilt with beefier power supplies. When I powered up this time the unit it stayed on. Phew! With the unit on I measured the voltages against the chart. Everything checked out fine so at this point I can officially declare PROJECT COMPLETE.

The pre-amp was installed inside an original H/K walnut cabinet. This cabinet has a few scratches and dings that need to be removed with a refinishing project. However, I have my father's mint condition cabinet in storage just waiting to house a refurbished Citation I. I will probably save it for when I refurbish my father's unit. But because I have a blemish free cabinet I don't feel a pressing need to refinish this one at present.

So, what tubes did I install in the completed pre-amp? I chose to use NOS Amperex tubes for the 12AX7 positions. NOS Mullard 12AT7WA tubes were used in the line stage positions V3, V4, V8, V9. These Mullards are the later model military tubes that are usually found boxed as CV4024. For the V5 position I chose to use a relatively cheap RCA 12AT7 tube. I was advised not to put an expensive tube in V5 because this tube only serves to light the power lamp and is used for the center channel line out. If you don't use the center channel, then why waste a good tube?

My final photo for this project is shown below. This is my system. Placed on top is a Music Hall MMF-7 turntable on the left alongside the new Citation I. Down below you can see two Citation II amplifiers. Both have been completely refurbished using all of Jim McShane's kits and parts. At present I only have one amplifier in use. The intention is to use both amplifiers. I haven't decided yet if I will bi-amp them with my Joseph Audio speakers or wire them as monoblock units. The shelving unit is from Salamander.

Time Spent: ~4 hours

So ends the project. I hope there are Citation fans out there who enjoyed reading this blog. This project was a lot of work, but I enjoyed all of it. I hope there were things to be learned for everyone who visited. What's next? I don't think I'll be doing a second Citation I right away. I have a couple of Citation II amps that I may work on next. But, the very next thing on my list is to hook this new pre-amp up to my system and see how it sounds. I hope you check back from time to time to read my report.

Once again, thanks to everyone for stopping by and reading. Goodbye for now.

Sunday, August 29, 2010

Saturday, August 28, 2010

Citation I Refurb - Final Assembly

So where were we? Hard to remember, it's been so long. Embarassing to say that the last post was March 30. And coincidentally, we left off on page 30 of the assembly manual. Let's continue.

Speed nuts are installed and the left hand rail is attached. The flexible metal tubing from the front side of the panel is clamped to the rail and the bare metal portion is soldered to the clamp. I'm not sure if the soldering is for grounding of the metal tubing in order to shield the wires from eletrical interference or simply to provide a secure attachment. The front panel and side rail assembly is shown in the following two photos.

The main chassis is attached next. The main chassis up to this point is comprised of the rear deck (RCA inputs and outputs), the tube sockets, and the A and B terminal boards. After attachment of the main chassis the unit is seen from the front and top views in the next two photos. It's really starting to look like it's nearing completion now.

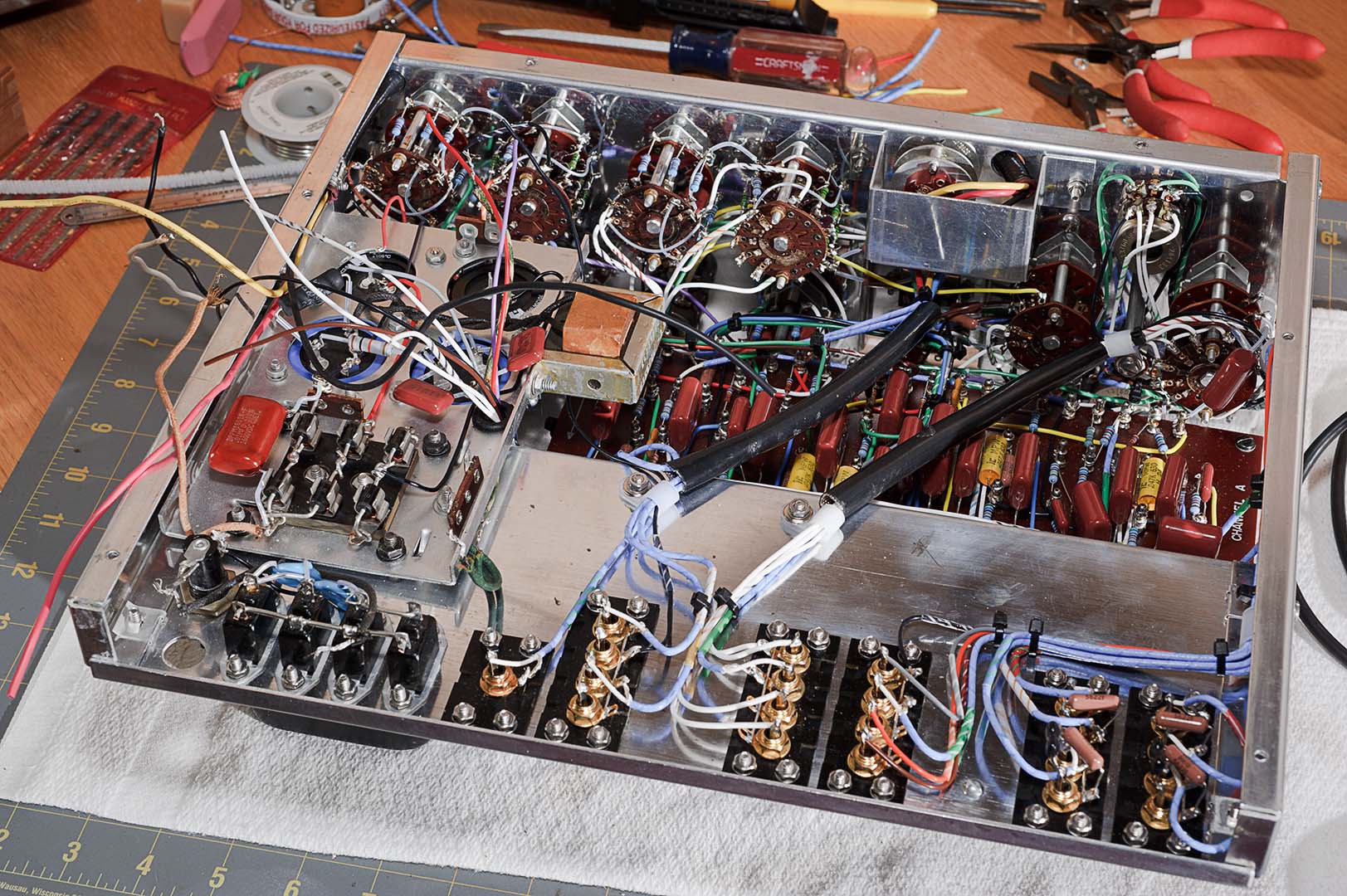

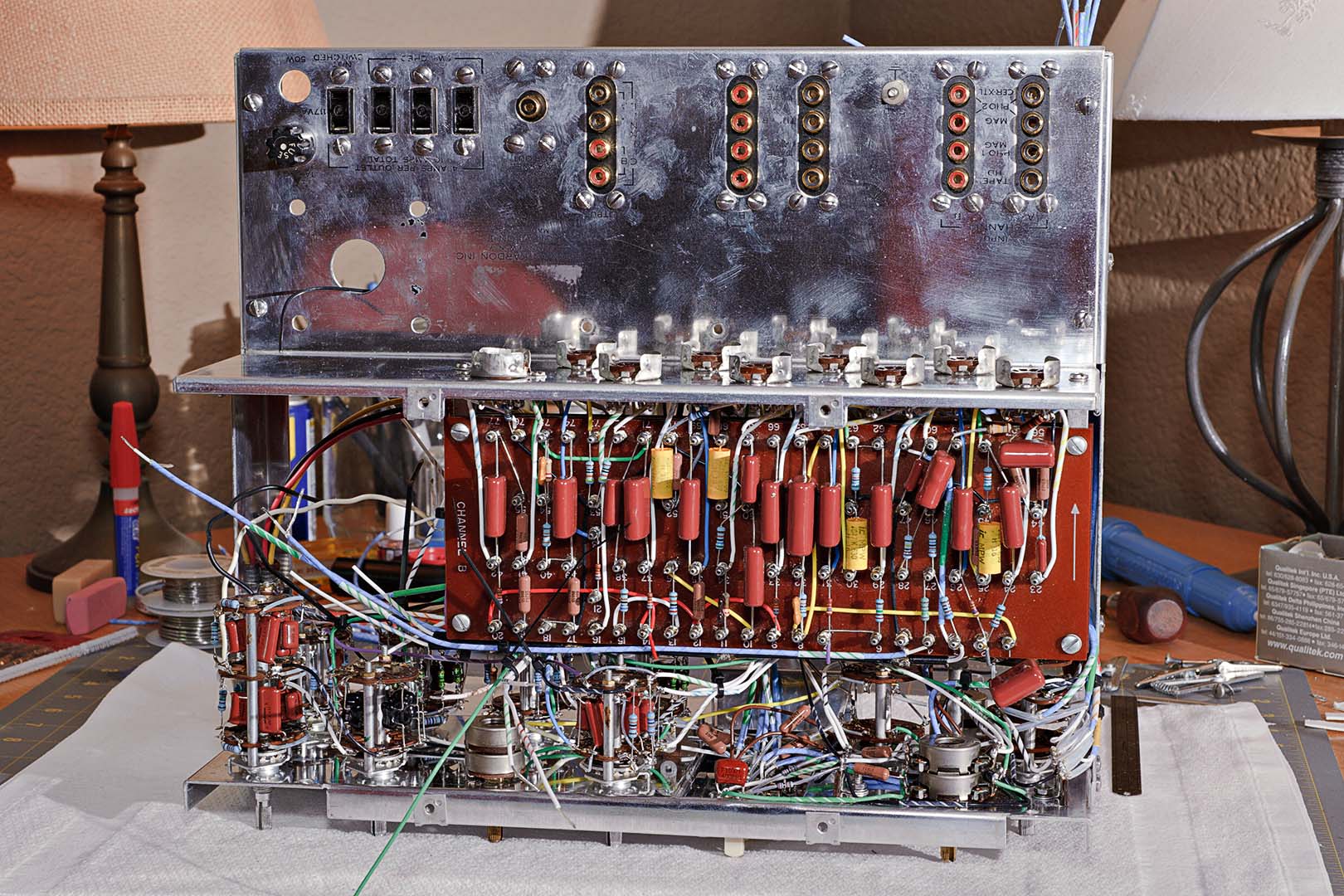

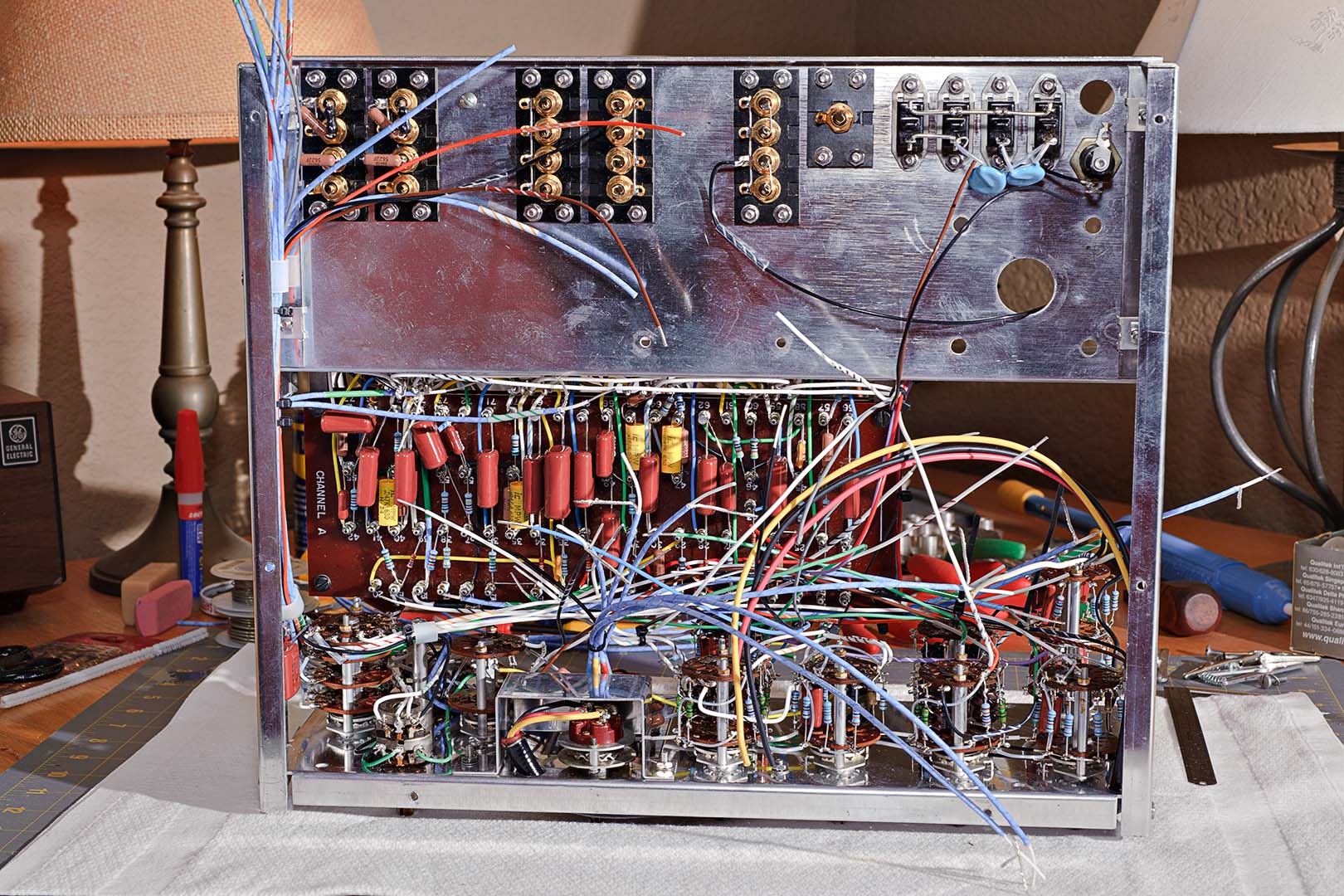

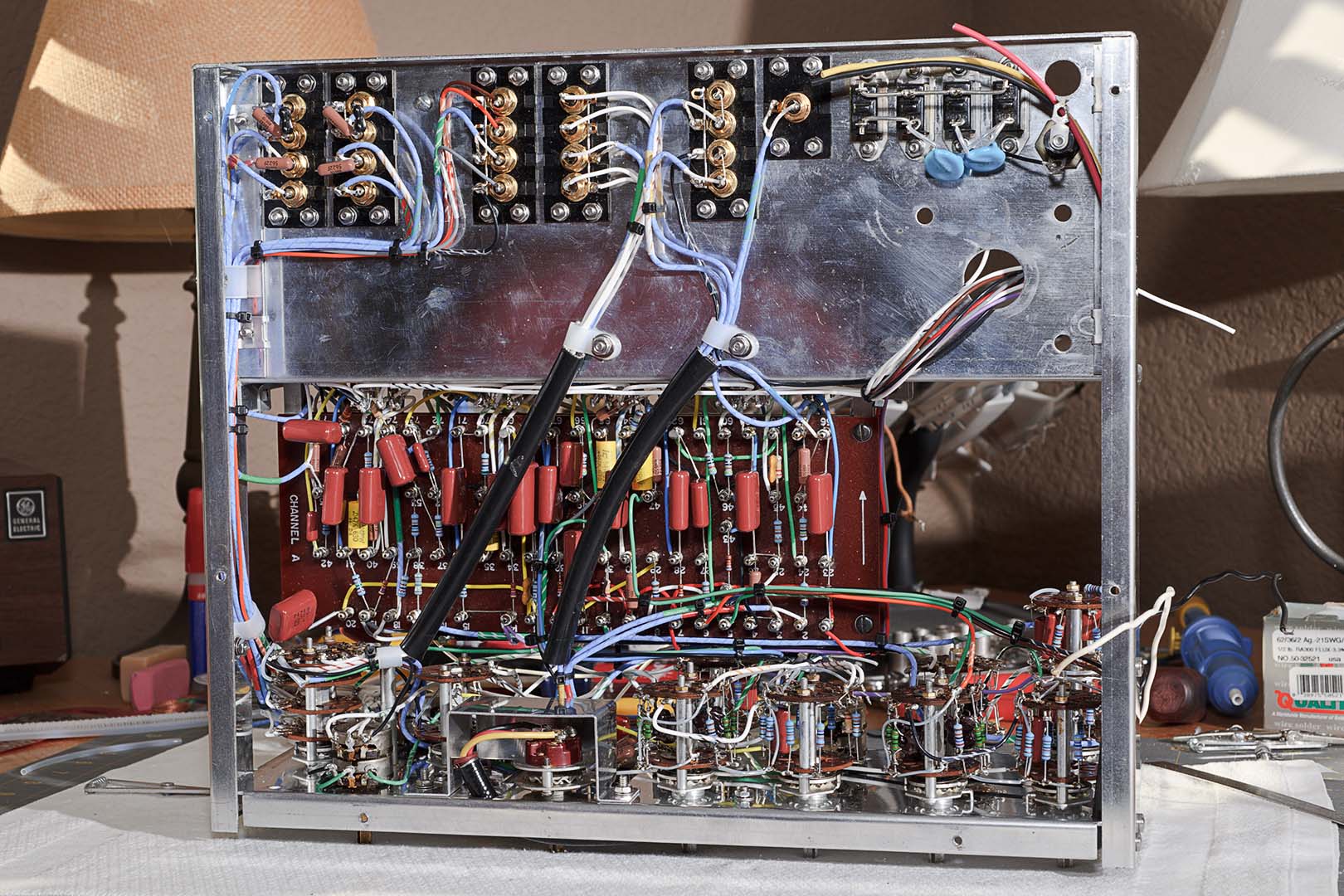

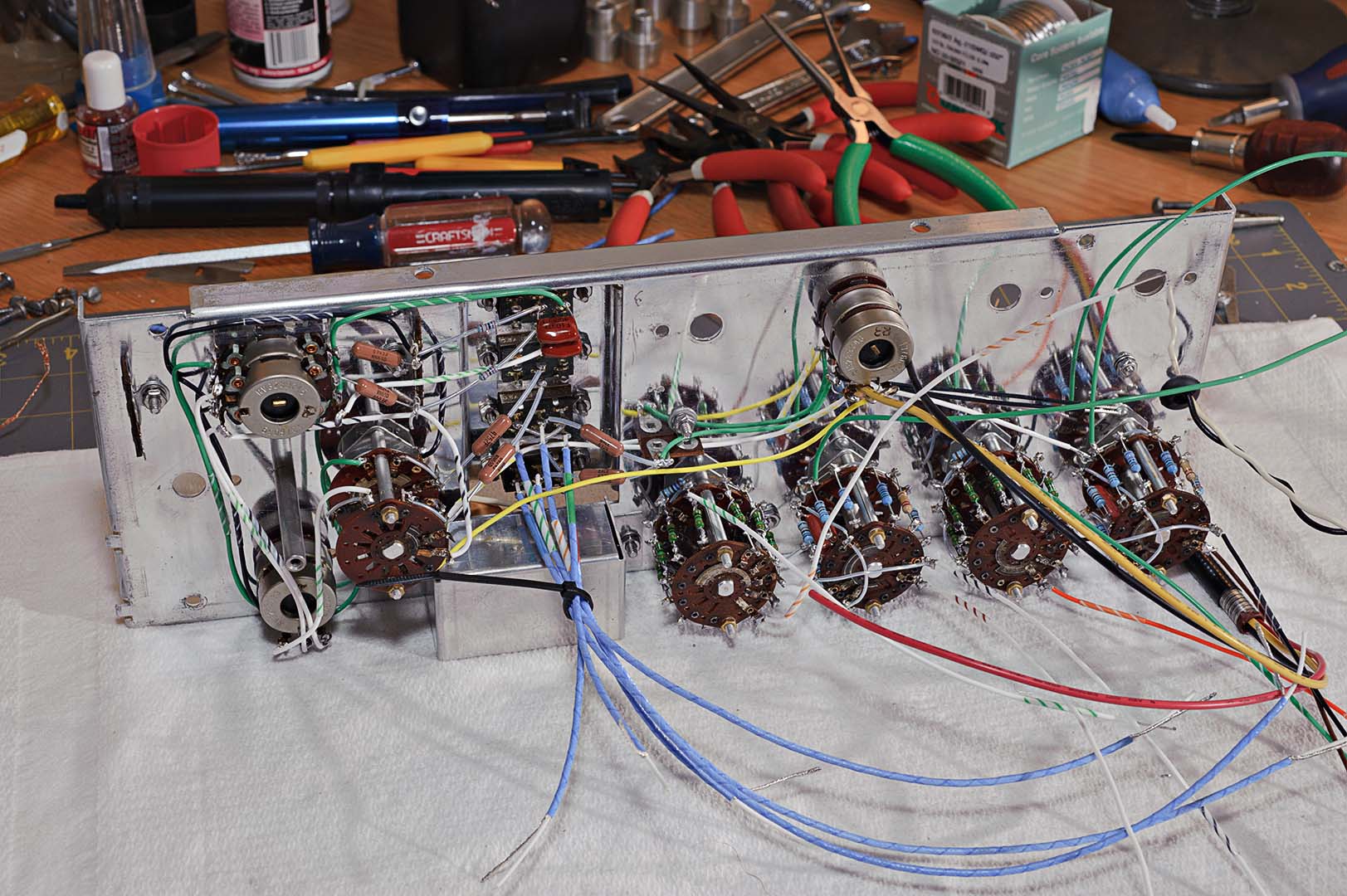

And now a view from underneatch at the Channel A side of the chassis. Now this looks to be a bit of a mess. It looks like a plate of spaghetti. The reason the underside looks so messy compared with the top is that most of the remaining wires that need connection are located on the underside as they run to the RCA jacks on the rear deck.

The remainder of page 31 and the first half of page 32 are a long list of steps to route and connect the wire running to the RCA strips on the rear deck. There's nothing out of the ordinary to point out here. Follow each step in the manual and be neat in the bundling and routing of the wires. New plastic nylon clamps were used to secure the main wire bundles running to the rear deck. Harman Kardon did a good job in the instructions of laying out a neat chassis. Following their steps and using small cable ties in place of the original black tape should result in a tidy appearance.

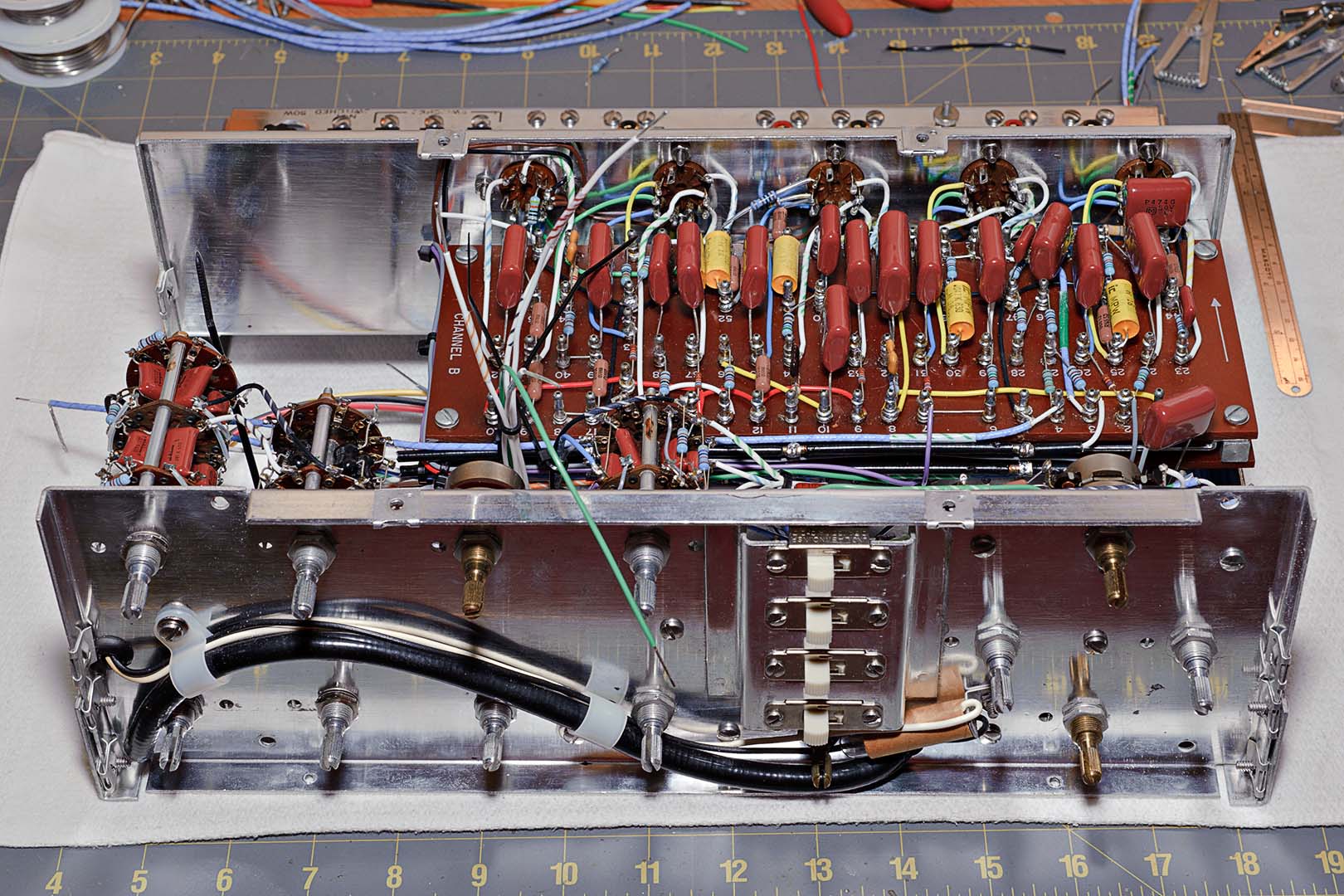

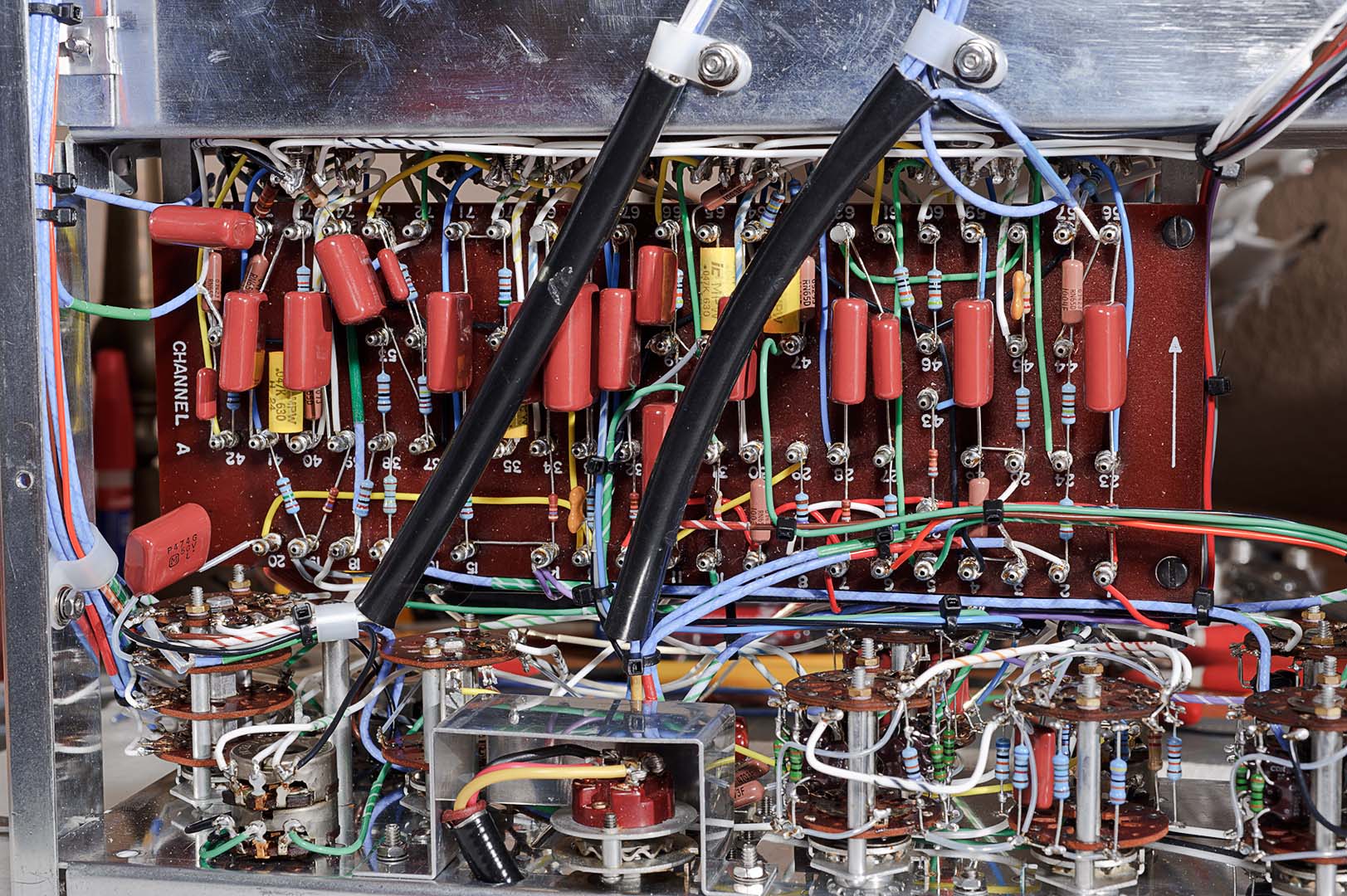

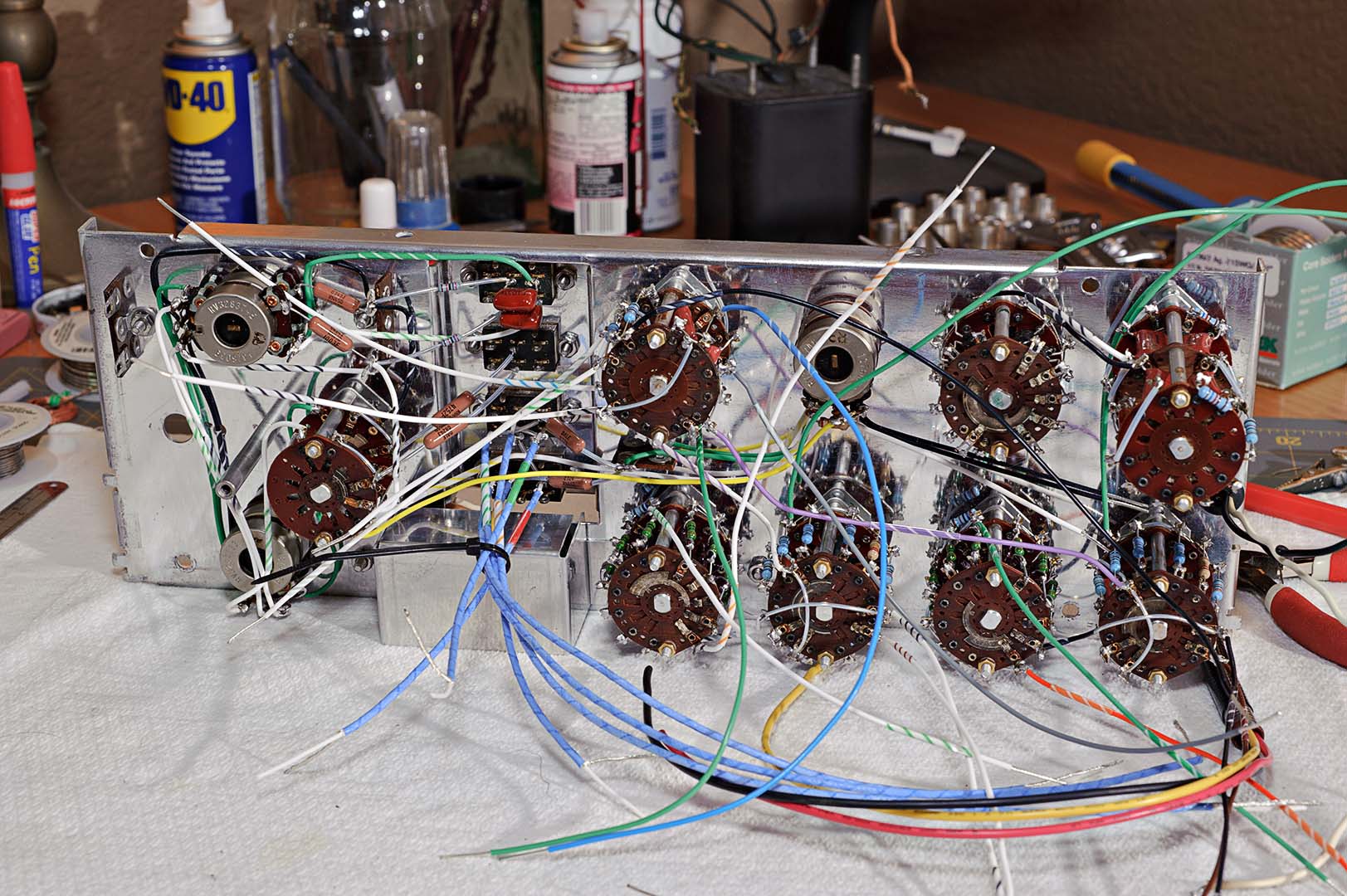

The second half of page 32 and all of page 33 deal with connecting the remaining front panel switch wires to their proper terminations on the terminal boards. Again, there's nothing complicated or noteworthy here. As commented on above, simply follow the instructions step by step. If there's is any advice to give out it would simply be to repeat the neatness theme. If you work carefully, following the instructions, you almost can't help but be neat. The following two pictures show what the underside of the chassis looks like after the wiring of terminal board A is complete.

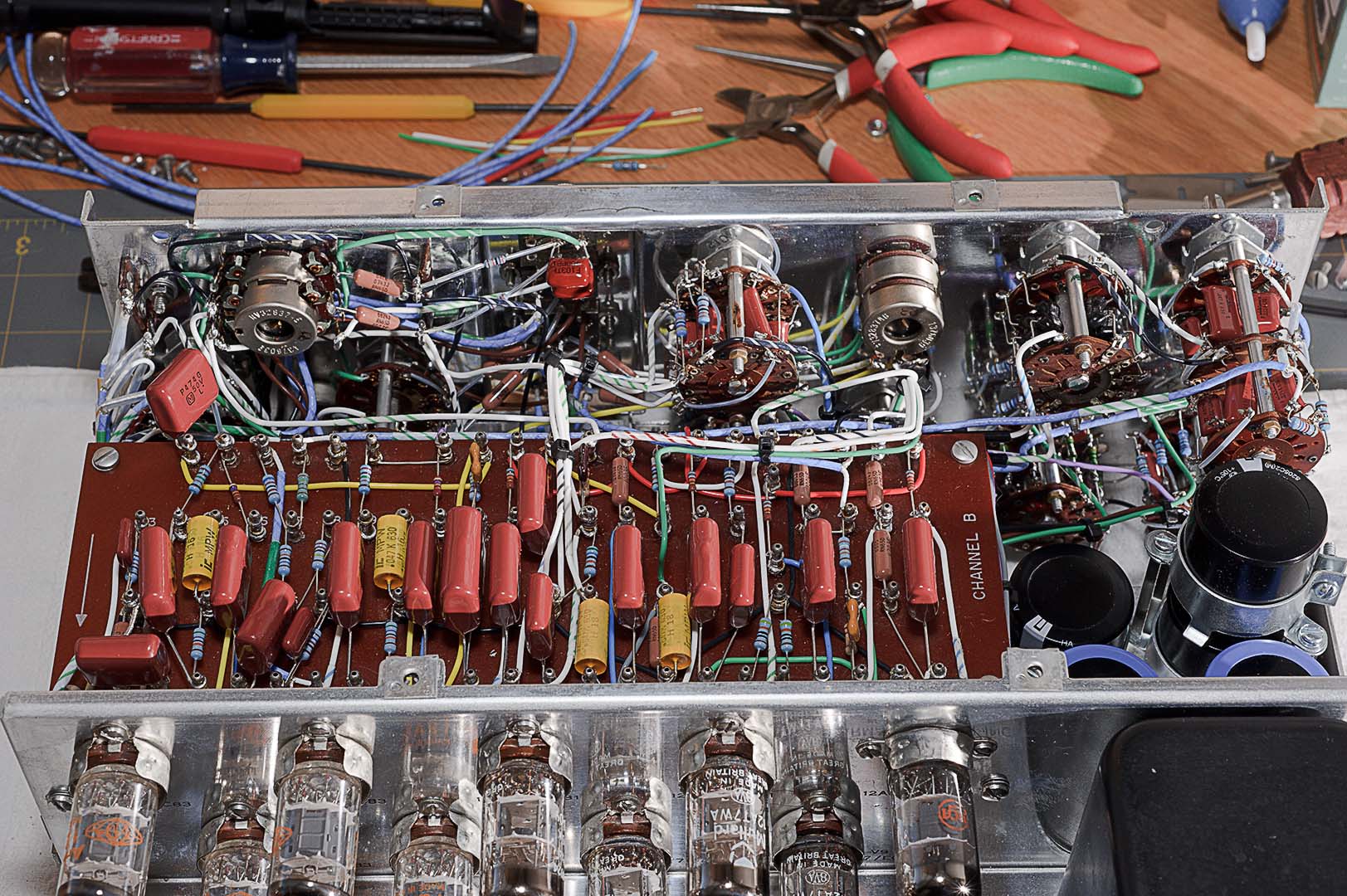

Once the underside and terminal board A are complete the chassis is flipped over and wiring of terminal board B is completed. The completed topside is shown below. In the two photos above and the one below you can no doubt see the striped labels that were wrapped around many of the wires. You may have to click on the image to zoom in. The use of laser labels for creating "striped insulation" wires seems to have worked out well. The proof of how well it worked won't come for a couple of years. When the chassis is opened up in 3 or 4 years' time will the labels still be wrapped snugly around the wires. I'm actually betting that they will be.

That completes the wiring of the switches and the terminal boards. We're almost finished. The remaining work is to install the power supply section that was completed a long time ago. And after that is the final assembly of the enclosure and knobs.

Total Time: ~12 hours

Speed nuts are installed and the left hand rail is attached. The flexible metal tubing from the front side of the panel is clamped to the rail and the bare metal portion is soldered to the clamp. I'm not sure if the soldering is for grounding of the metal tubing in order to shield the wires from eletrical interference or simply to provide a secure attachment. The front panel and side rail assembly is shown in the following two photos.

The main chassis is attached next. The main chassis up to this point is comprised of the rear deck (RCA inputs and outputs), the tube sockets, and the A and B terminal boards. After attachment of the main chassis the unit is seen from the front and top views in the next two photos. It's really starting to look like it's nearing completion now.

And now a view from underneatch at the Channel A side of the chassis. Now this looks to be a bit of a mess. It looks like a plate of spaghetti. The reason the underside looks so messy compared with the top is that most of the remaining wires that need connection are located on the underside as they run to the RCA jacks on the rear deck.

The remainder of page 31 and the first half of page 32 are a long list of steps to route and connect the wire running to the RCA strips on the rear deck. There's nothing out of the ordinary to point out here. Follow each step in the manual and be neat in the bundling and routing of the wires. New plastic nylon clamps were used to secure the main wire bundles running to the rear deck. Harman Kardon did a good job in the instructions of laying out a neat chassis. Following their steps and using small cable ties in place of the original black tape should result in a tidy appearance.

The second half of page 32 and all of page 33 deal with connecting the remaining front panel switch wires to their proper terminations on the terminal boards. Again, there's nothing complicated or noteworthy here. As commented on above, simply follow the instructions step by step. If there's is any advice to give out it would simply be to repeat the neatness theme. If you work carefully, following the instructions, you almost can't help but be neat. The following two pictures show what the underside of the chassis looks like after the wiring of terminal board A is complete.

Once the underside and terminal board A are complete the chassis is flipped over and wiring of terminal board B is completed. The completed topside is shown below. In the two photos above and the one below you can no doubt see the striped labels that were wrapped around many of the wires. You may have to click on the image to zoom in. The use of laser labels for creating "striped insulation" wires seems to have worked out well. The proof of how well it worked won't come for a couple of years. When the chassis is opened up in 3 or 4 years' time will the labels still be wrapped snugly around the wires. I'm actually betting that they will be.

That completes the wiring of the switches and the terminal boards. We're almost finished. The remaining work is to install the power supply section that was completed a long time ago. And after that is the final assembly of the enclosure and knobs.

Total Time: ~12 hours

Tuesday, March 30, 2010

Citation I Refurb - Front Panel Continued

There is no lead-in to this blog post. We are simply going to continue work on the front panel, picking up in the middle of page 28 in the assembly manual. The mode switch is installed first. The wires on the wafer are connected to the balance control and one of the terminal strips. The pair of 47K ohm resistors from the mode control are connected to one of the slide switches.

At this point allow me to make a comment. The instructions on this page of the manual make a statement to "Make certain that the wires from these resistors do not touch each other or any of the other pins on the switch." I ensured this by slipping on lengths of Teflon tubing to these and all resistors and capacitors installed inside the chassis that have appreciable length leads. You will see this in the photos which follow.

The blend control was installed next. After locking in place several wires and a 220K ohm resistor are connected from the blend control to various points on the front panel. The photo below shows the state of the front panel at this point. It is worth noting at this point that the panel is still relatively bare.

The next switches to be installed are the treble and bass switches, S4 through S7. The aluminum cover for the power switch is also installed at this time. With each switch that is installed the panel becomes more cluttered with wires that will not be attached to their destinations until later. The photo below shows the work at this point.

The turnover and rolloff switches are installed next and wired together. This is followed by the installation of the low-cut switch. Wires from the switch are connected to the bass switches. The photo below shows the state of the front panel at this point. Note how cluttered the panel now is before the wires are organized.

The next steps of the instructions call for taping together groups of these wires that will be routed to similar destinations on the two terminal boards. Of course, I will be using cable ties instead of tape.

Next comes the installation of the last switch, the function switch. This is the switch that I referred to earlier as a medusa's head. After the switch is installed the various wires, mainly the shields from the shielded wires, are connected to the proper destination points on the chassis as indicated in the manual. The twisted shields are all covered with lengths of Teflon tubing for insulation from each other.

At this point I found that a couple of the twisted shields, even after careful measuring, simply did not reach their destination on the terminal strip comfortably. I also found that even with insulation tubing placed over the shield wires there still seemed to be a danger that the wires could possibly touch each other. I stopped my work at this point to think through what to do. In the end I picked out a couple of wires that seemed to be the biggest offenders and simply removed them and replaced them with wires of slightly different lengths.

The next step is to group and tape together the wires from the function switch. The wires are grouped as indicated in one of the supplied pictorial diagrams. Because I used cable ties in place of tape I did not fully bind the wires. Instead, I left a bit of slack in the cable ties so that I would be able to adjust the ties later, after the wires had been routed to their destinations inside the chassis.

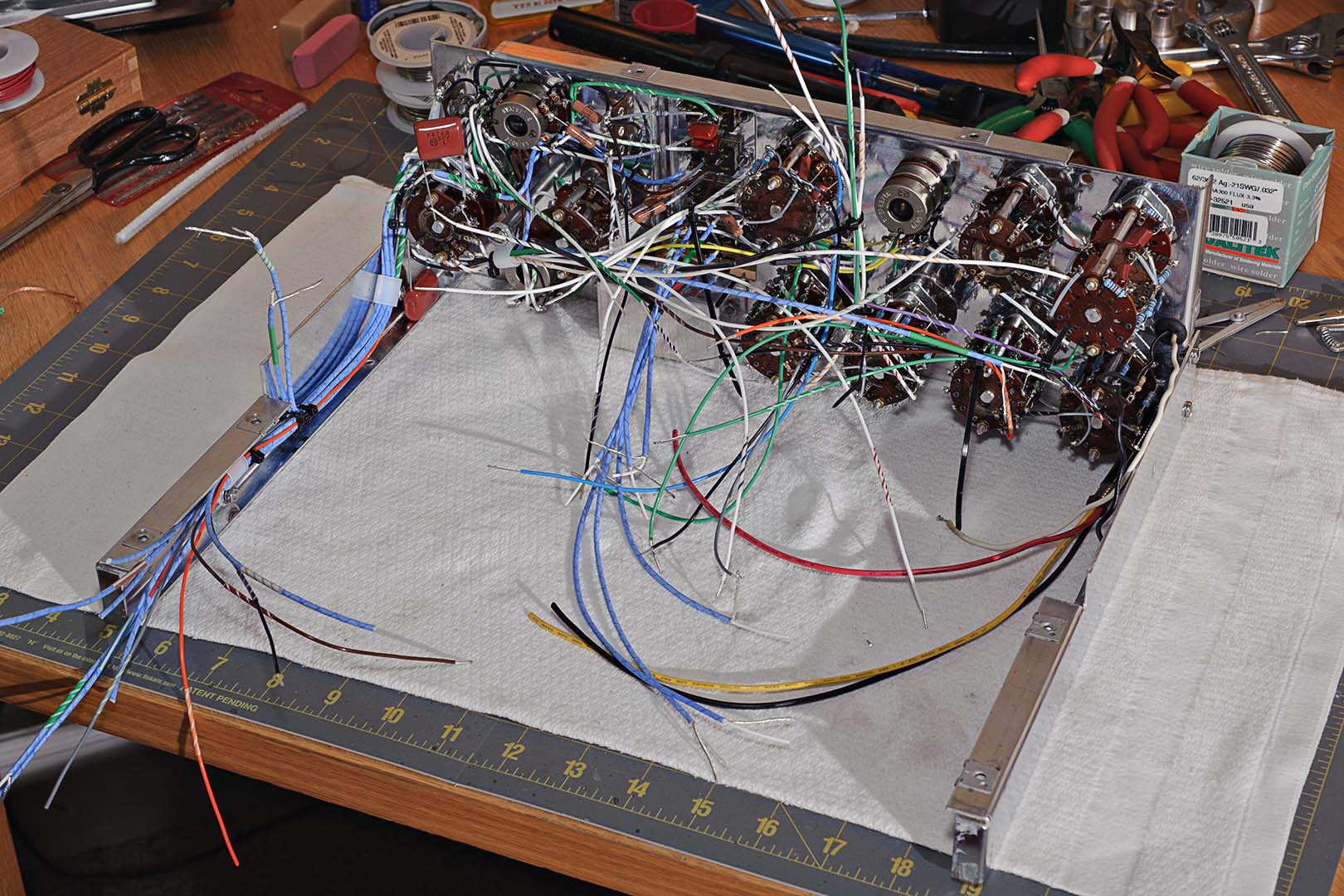

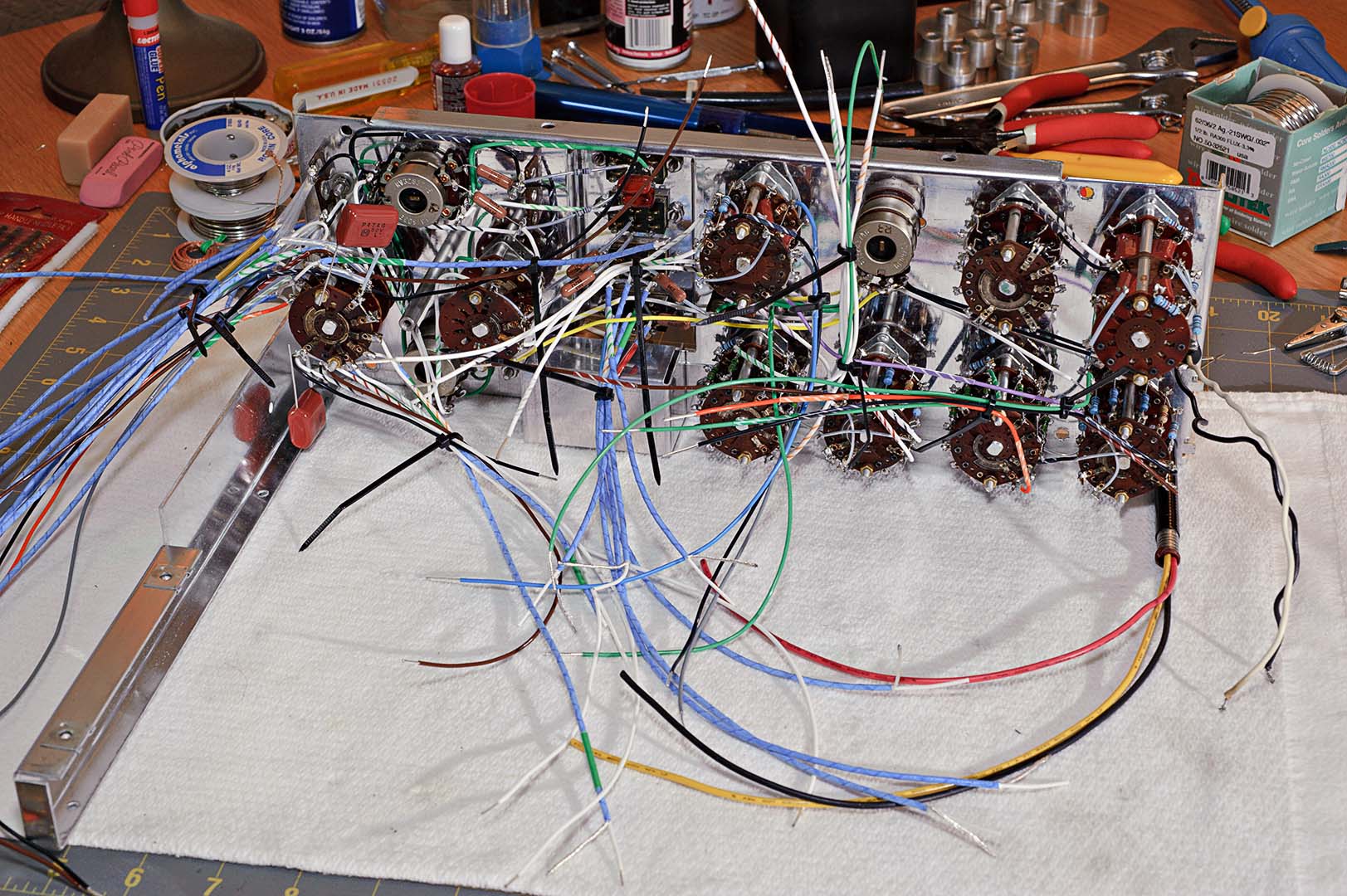

Finally, the right side rail (on the side next to the function switch) is attached. At this point the front panel looks like the following photo. There's a lot of wires there. Think what it would look like if the loose wires weren't cabled together in neat bundles.

I'm now one-quarter down on page 30. The final steps of the front panel wiring are to neatly rout the wires from the function switch. The manual is very clear in pointing out how important it is to dress the wires properly so that a neat and professional appearance is obtained. This includes making sure to dress the wires in each bundle all parallel to each other, no crossing of wires. This makes for a neat appearance as well as keeping the bundle diameter to a minimum.

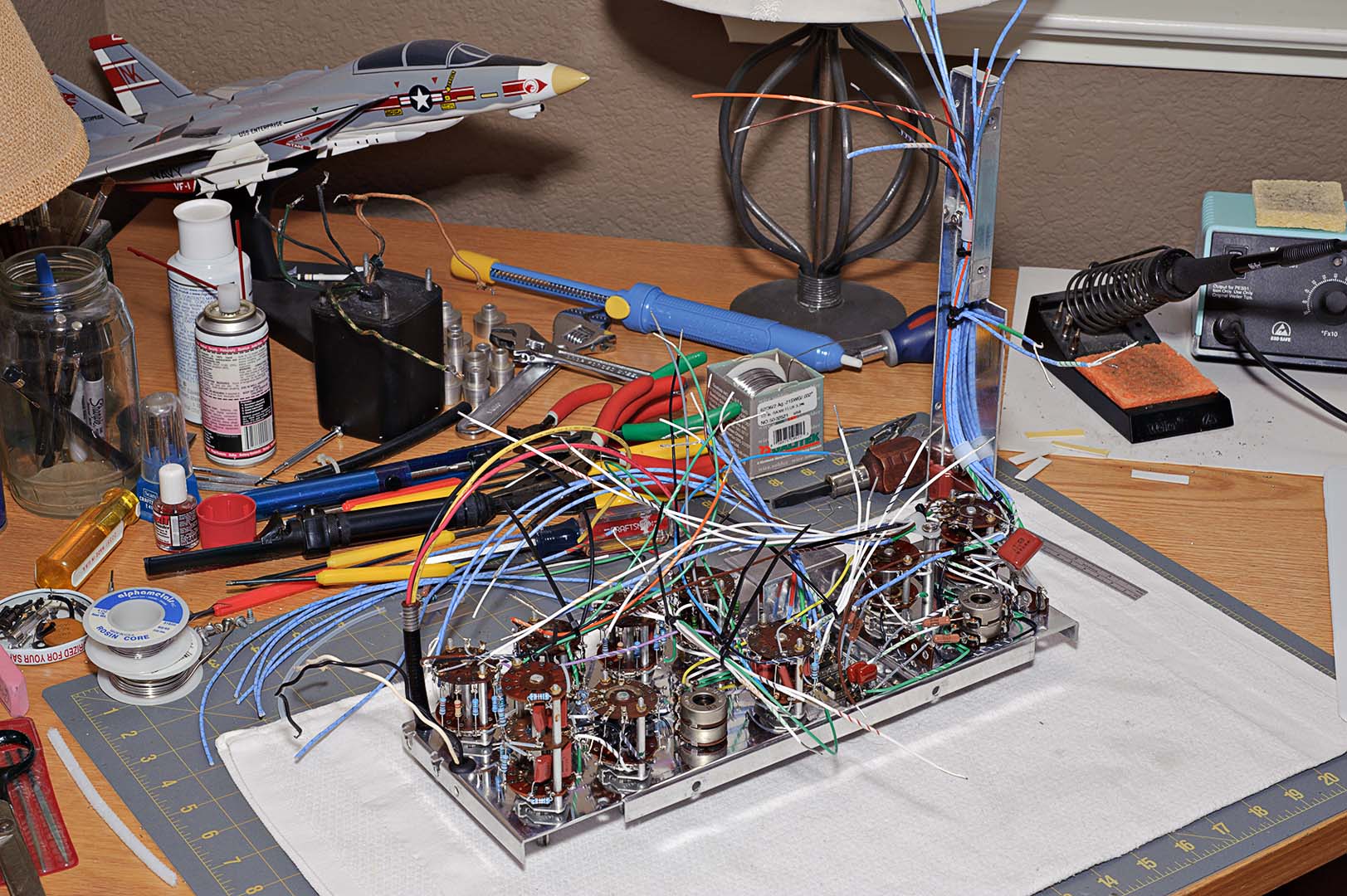

That is the only comment I can make at this point. The rest of the work is simply following the instructions as outlined in the assembly manual. New plastic cable clamps were used where specified in the instructions. When you reach the end of page 30 the front panel work has been completed. The result is shown in the following photo. Don't be confused by the extra shielded wires on the left to the rear of the panel (lying on the desk). These are extra shielded wire lengths for the next stage of construction and are not connected to the front panel.

That completes the front panel installation. As in my previous blog post I forget how long the front panel took to complete. I'll take a guess though.

Total Time Spent: ~8 hours

At this point allow me to make a comment. The instructions on this page of the manual make a statement to "Make certain that the wires from these resistors do not touch each other or any of the other pins on the switch." I ensured this by slipping on lengths of Teflon tubing to these and all resistors and capacitors installed inside the chassis that have appreciable length leads. You will see this in the photos which follow.

The blend control was installed next. After locking in place several wires and a 220K ohm resistor are connected from the blend control to various points on the front panel. The photo below shows the state of the front panel at this point. It is worth noting at this point that the panel is still relatively bare.

The next switches to be installed are the treble and bass switches, S4 through S7. The aluminum cover for the power switch is also installed at this time. With each switch that is installed the panel becomes more cluttered with wires that will not be attached to their destinations until later. The photo below shows the work at this point.

The turnover and rolloff switches are installed next and wired together. This is followed by the installation of the low-cut switch. Wires from the switch are connected to the bass switches. The photo below shows the state of the front panel at this point. Note how cluttered the panel now is before the wires are organized.

The next steps of the instructions call for taping together groups of these wires that will be routed to similar destinations on the two terminal boards. Of course, I will be using cable ties instead of tape.

Next comes the installation of the last switch, the function switch. This is the switch that I referred to earlier as a medusa's head. After the switch is installed the various wires, mainly the shields from the shielded wires, are connected to the proper destination points on the chassis as indicated in the manual. The twisted shields are all covered with lengths of Teflon tubing for insulation from each other.

At this point I found that a couple of the twisted shields, even after careful measuring, simply did not reach their destination on the terminal strip comfortably. I also found that even with insulation tubing placed over the shield wires there still seemed to be a danger that the wires could possibly touch each other. I stopped my work at this point to think through what to do. In the end I picked out a couple of wires that seemed to be the biggest offenders and simply removed them and replaced them with wires of slightly different lengths.

The next step is to group and tape together the wires from the function switch. The wires are grouped as indicated in one of the supplied pictorial diagrams. Because I used cable ties in place of tape I did not fully bind the wires. Instead, I left a bit of slack in the cable ties so that I would be able to adjust the ties later, after the wires had been routed to their destinations inside the chassis.

Finally, the right side rail (on the side next to the function switch) is attached. At this point the front panel looks like the following photo. There's a lot of wires there. Think what it would look like if the loose wires weren't cabled together in neat bundles.

I'm now one-quarter down on page 30. The final steps of the front panel wiring are to neatly rout the wires from the function switch. The manual is very clear in pointing out how important it is to dress the wires properly so that a neat and professional appearance is obtained. This includes making sure to dress the wires in each bundle all parallel to each other, no crossing of wires. This makes for a neat appearance as well as keeping the bundle diameter to a minimum.

That is the only comment I can make at this point. The rest of the work is simply following the instructions as outlined in the assembly manual. New plastic cable clamps were used where specified in the instructions. When you reach the end of page 30 the front panel work has been completed. The result is shown in the following photo. Don't be confused by the extra shielded wires on the left to the rear of the panel (lying on the desk). These are extra shielded wire lengths for the next stage of construction and are not connected to the front panel.

That completes the front panel installation. As in my previous blog post I forget how long the front panel took to complete. I'll take a guess though.

Total Time Spent: ~8 hours

Saturday, March 27, 2010

Citation I Refurb - Wiring the Front Panel

I'm back. Finally, after over 4 months. I'll be honest and admit that I'm actually further along on this project than the blog posts would indicate. With holidays and travel the blog just got pushed way down on the priority list. I don't want to leave this project unfinished, however, so let me complete the rest of the write-up. So where were we?

Way back on Nov. 21 I had just completed the switch wiring and was now ready to begin on the front panel, which is described at the bottom of page 26 of the assembly manual. I think I made mention in the last post that all of the hard work has been completed and the remainder of the step are pretty straight forward. This is mostly true.

The four slide switches were installed in the front panel followed by a new small rubber grommet. The AC switch was installed and a new #1815 pilot bulb was installed, even though the old one was still working. The pilot lamp assembly was mounted onto the panel and the wires routed through the new grommet.

The wires that run to the power switch were prepared next. This is the one place in the project that I did not use Teflon coated wire. Basically, I just couldn't find any wire of sufficient gauge that I could buy in small quantities. I ended up buying 25ft spools of 16 gauge PVC coated wire (80°C, 300V). I also could not find the original colors of blue, tan, and black. Instead, I had to settle for black, yellow, and red. Yellow replaced tan and red replaced blue. The wires were run through the original insulated metal tubing, mounted to the chassis using new plastic clamps, and soldered to the power switch.

The lug strips (TS4, TS5, and TS6) were installed. Finally the tubular spacer was attached and the loudness and balance controls were mounted. The end result at this stage are the two photos below, one from each side of the panel.

The next steps in the manual cover the wiring of the loudness and balance controls as well as the preliminary wiring of the slide switches. In the photo below you can see more examples of the labels that I used to indicate the striped wiring. You can also see that there is also a fair amount of shielded wiring that runs from the slide switches, specifically S13 and S14 (stereo reverse and phasing switches).

At this point I am going to stop. My bookmark is on the middle of page 28 of the assembly manual. With any luck I can complete this assembly in just a couple more blog posts. I would like to be able to say how much time the above work took to complete. Unfortunately, it was four months ago and I just don't remember. I'll give an estimate anyway.

Time Spent: ~2-3 hours

Way back on Nov. 21 I had just completed the switch wiring and was now ready to begin on the front panel, which is described at the bottom of page 26 of the assembly manual. I think I made mention in the last post that all of the hard work has been completed and the remainder of the step are pretty straight forward. This is mostly true.

The four slide switches were installed in the front panel followed by a new small rubber grommet. The AC switch was installed and a new #1815 pilot bulb was installed, even though the old one was still working. The pilot lamp assembly was mounted onto the panel and the wires routed through the new grommet.

The wires that run to the power switch were prepared next. This is the one place in the project that I did not use Teflon coated wire. Basically, I just couldn't find any wire of sufficient gauge that I could buy in small quantities. I ended up buying 25ft spools of 16 gauge PVC coated wire (80°C, 300V). I also could not find the original colors of blue, tan, and black. Instead, I had to settle for black, yellow, and red. Yellow replaced tan and red replaced blue. The wires were run through the original insulated metal tubing, mounted to the chassis using new plastic clamps, and soldered to the power switch.

The lug strips (TS4, TS5, and TS6) were installed. Finally the tubular spacer was attached and the loudness and balance controls were mounted. The end result at this stage are the two photos below, one from each side of the panel.

The next steps in the manual cover the wiring of the loudness and balance controls as well as the preliminary wiring of the slide switches. In the photo below you can see more examples of the labels that I used to indicate the striped wiring. You can also see that there is also a fair amount of shielded wiring that runs from the slide switches, specifically S13 and S14 (stereo reverse and phasing switches).

At this point I am going to stop. My bookmark is on the middle of page 28 of the assembly manual. With any luck I can complete this assembly in just a couple more blog posts. I would like to be able to say how much time the above work took to complete. Unfortunately, it was four months ago and I just don't remember. I'll give an estimate anyway.

Time Spent: ~2-3 hours

Subscribe to:

Posts (Atom)