Yesterday's post left off at the top of page 19. Let's pick it up from there, which begins with the wiring of the phono sockets, newly upgraded to gold plate.

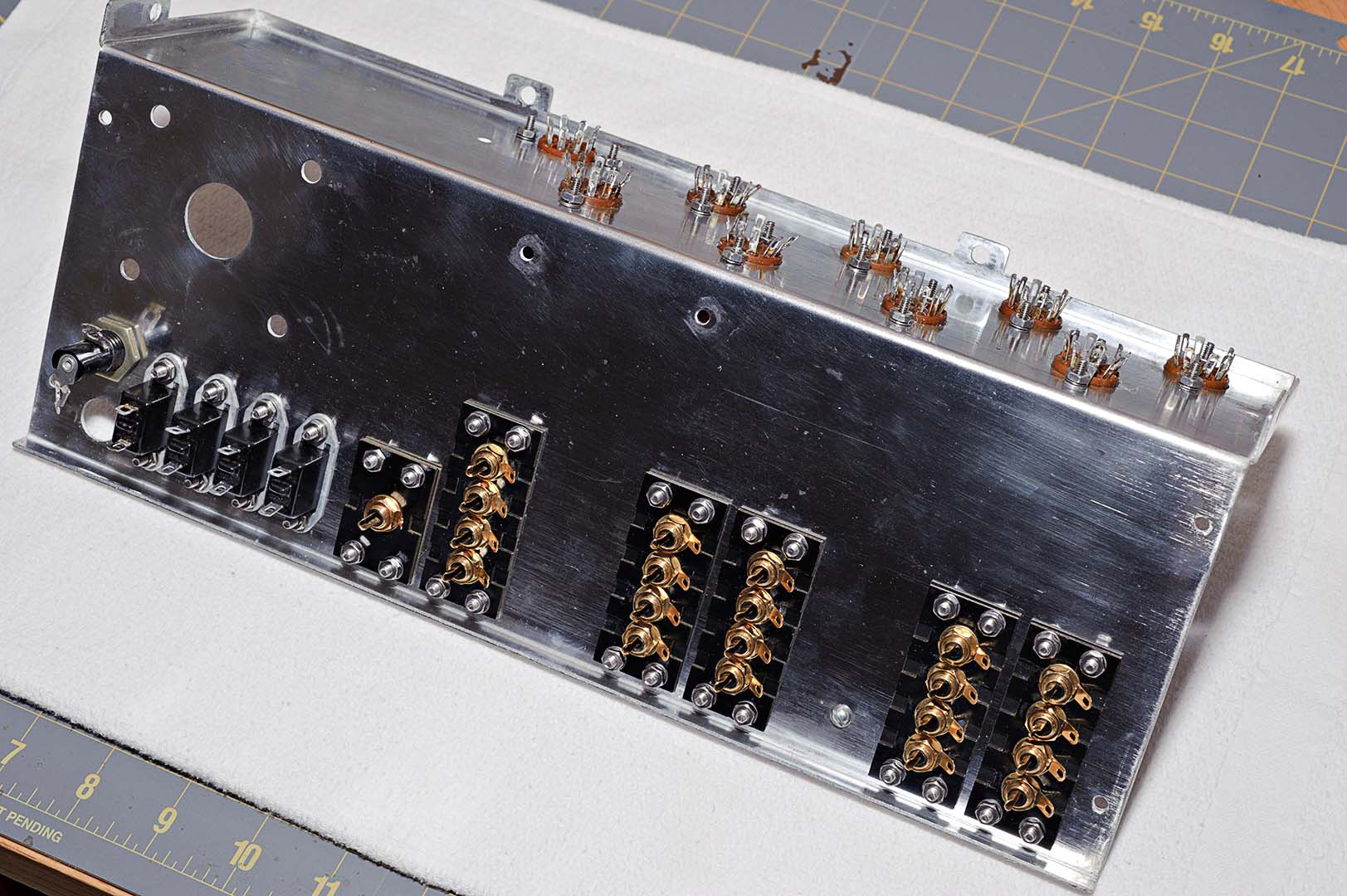

But first, let's pause here and go back two posts to a question I posed then. Does it matter which side you position the ground lugs on when assembling the new phono strips? Like a lot of things in life the answer is "it depends". If you use RCA phono sockets that all have the same color insert then the answer is "No". If you really don't care how neat your wiring job is the answer is also "no". However, if you're using color keyed phono socket inserts like I am and you care about neatness then the answer is "Yes". Here's a photo repeated from yesterday's post showing the chassis after the mounting of the RCA strips.

See how I have mounted the strips with the grounding lugs all pointed the same way? This is wrong! Unfortunately, I didn't catch my error in time. I proceeded as indicated in the manual and completed the wiring of phono sockets. When finished I looked at my work and then thought about how all the other wires that connected to the phono sockets were going to be arranged (or "dressed" as seems to be the proper term) in later stages of assembly.

See the two wide sections of bare chassis that run between the parallel strips of phono sockets. Those bare areas are where you want to run the wires to the sockets. So what you really want is to mount the phono strips such that the ground lugs are located next to the open chassis areas. If you do like I did in the upper photo the wires will have to be dressed over the top of the sockets to reach the ground lugs. Now look at the following photo.

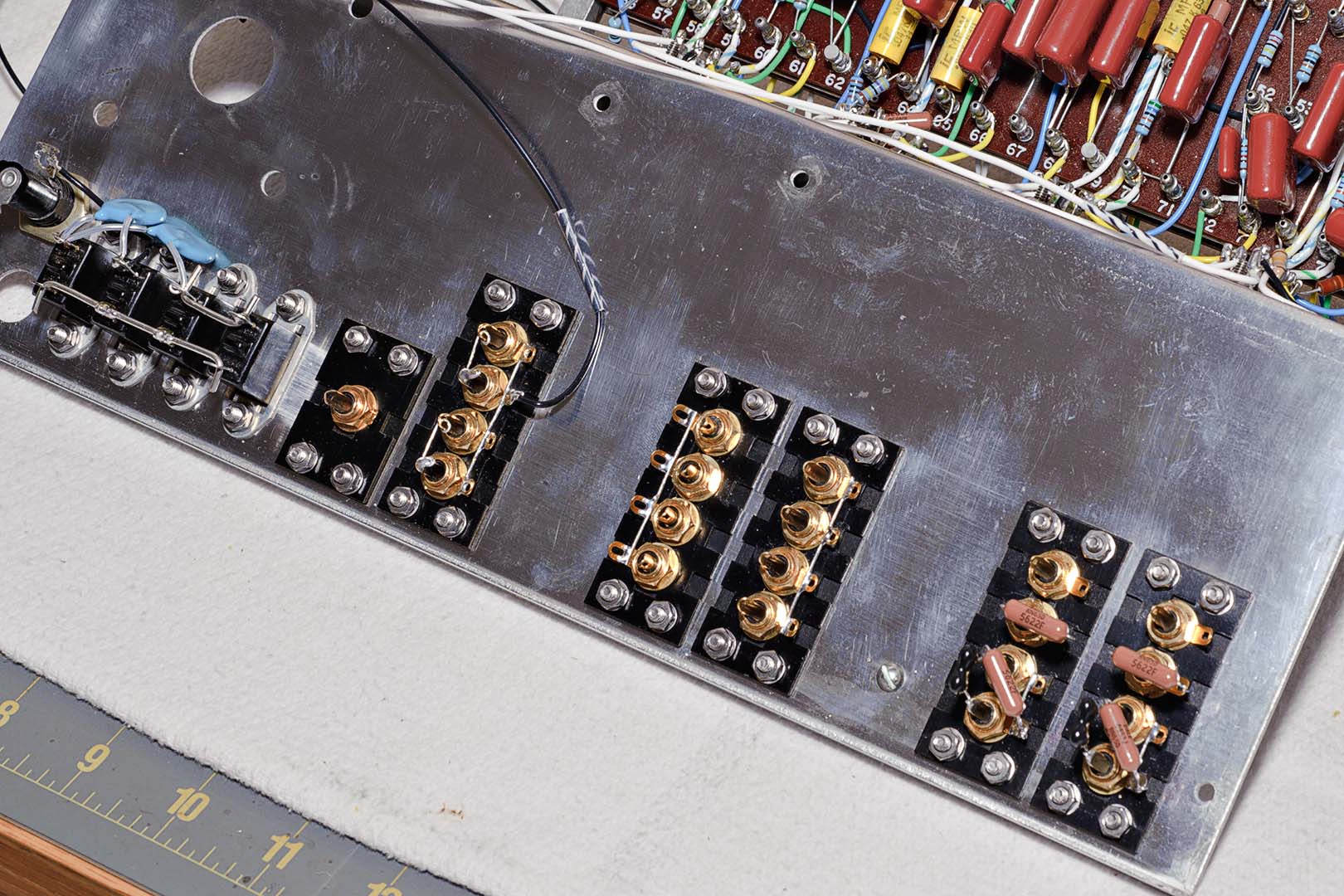

This is the arrangement that I ended up with. See how I flipped around one of the strips, the fourth strip from the right? I couldn't do that with the second strip from the right because 1) it was already wired and 2) this is one of the strips where I filed down the retaining washers so the grounds wouldn't touch. Even if I desoldered the components I would still have had to remove the individual sockets themselves and remount them. After the finger torture I went through to assemble them in the first place I was not about to disassemble and reassemble them again. Similary, the last strip of four on the left cannot be flipped around either. This strip has two red and two black inserts. Flipping the strip around will make the red inserts the A channel and black will be B.

I corrected the orientation of the one strip I could change and left it at that. If this is the worst mistake I make in the assembly of the unit I will have done an alright job. But this does make a point. Think out your work carefully. And if you are using replacement parts with different geometrys than the originals then think ahead to issues that may arise.

The rest of the steps on page 19 were completed in sequence. One item of note is the substitution of the original dual section triple lead 0.01 μF, 1400V capacitor. From on-line discussions with members of The Citation Sound forum, particularly Paul Wolfe, I learned that this was a "safety" capacitor. Except that it really isn't a true safety capacitor. I replaced the stock cap with two X1/Y1 0.01 μF safety capacitors from JustRadios.com. This safety cap has been tested to withstand 2500V AC for one minute. Convenience outlet CO4 was used as the common tie point. JustRadios.com has a good article on safety capacitors, the different types, and their uses. Highly recommended reading for those restoring old vintage equipment.

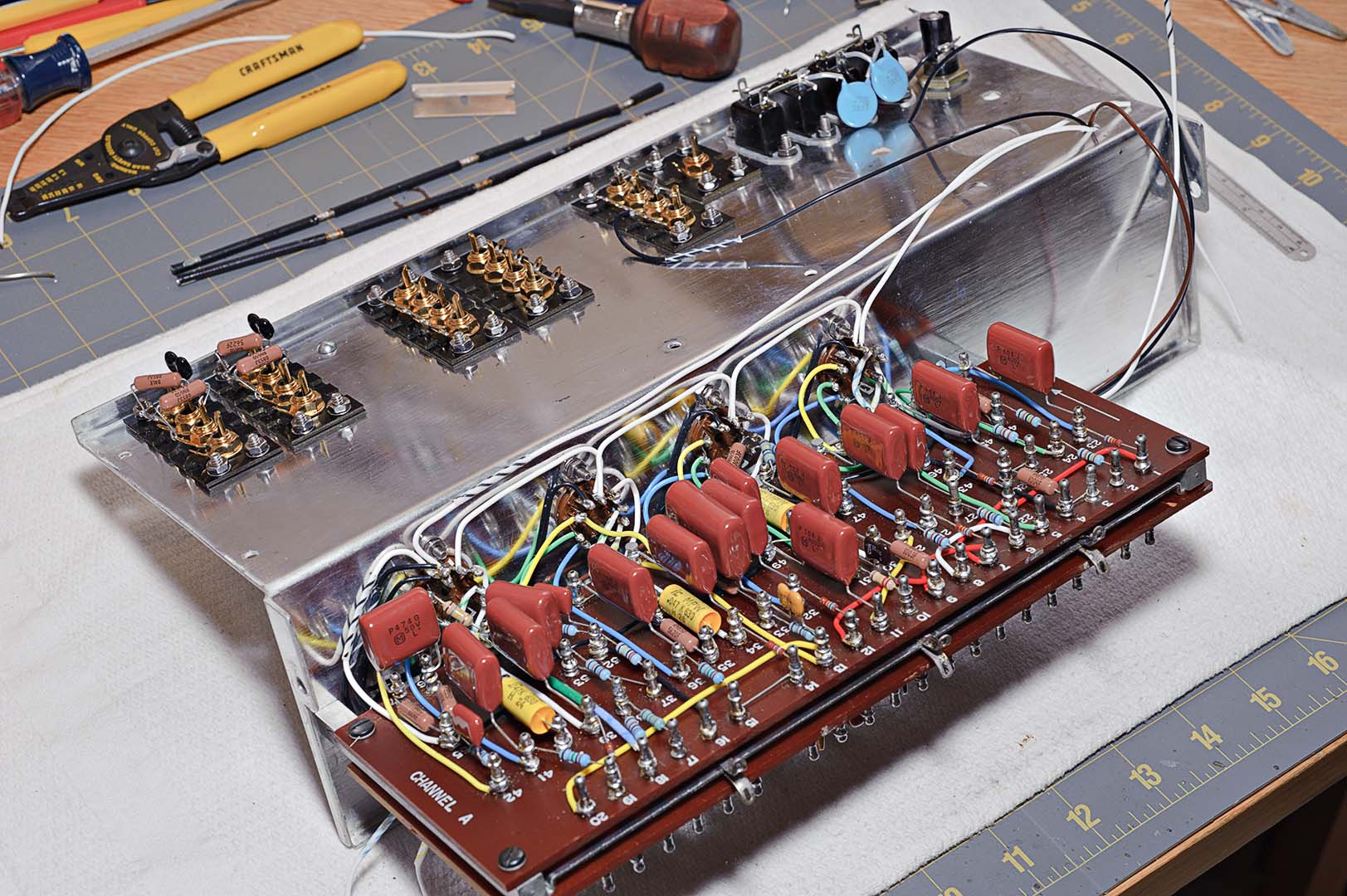

The last step on page 19 is the attachment of the terminal board assembly to the chassis. The terminal board assembly is described on page 16 of the manual. If you recall from a couple posts back I did not assemble the terminal boards at that time due to the fact that I saw no way to store the assembly without bending some of the wired components. So back to page 16 to complete the terminal board shield assembly and then back to page 19 to attach it to the chassis.

With the terminal board assembly now attached to the chassis the next steps are to connect all the wires from the terminal boards to the tube sockets. The steps for this are laid out on pages 20 and 21, and a bit on page 22. There are a lot of steps on these two pages, but not really much to comment on. Well, I do actually have a couple comments at this point.

The first is that if you choose to use 20 gauge stranded wiring like I did you will have to be very careful when attaching the wires. As I've already described way, way back I found this wire hard to work with for delicate wiring situations like the tube sockets. Once you tin the ends, and you must do this, the wire becomes very stiff. On top of that the pin lugs do not have very large holes. For those pins that have multiple wires attached the size of the wire makes it a very tight squeeze. But I took care and completed this wiring stage without incident.

My second comment is a general one regarding exposure of bare wire. Whenever possible I am using clear Teflon tubing as sleeving to cover lengths of exposed wire. For example, in the wiring of the tube sockets there are resistors running between the board and the sockets. I use Teflon sleeving to insulate the longer resistor leads. Likewise, I used Teflon to cover the leads of the X1/Y1 safety caps described previously. The one big exception is that I did not use any sleeving on the components mounted entirely on the terminal boards.

After completion of the tube socket wiring I was left with the chassis as depicted in the photo below.

Let's power through one more page of assembly instructions before ending this post. Continuing with the steps on page 22 I now attached the black flexible metal tubing to the edge of the terminal boards. You can see the black tubing lengths sitting on the desk above the chassis in the previous photo.

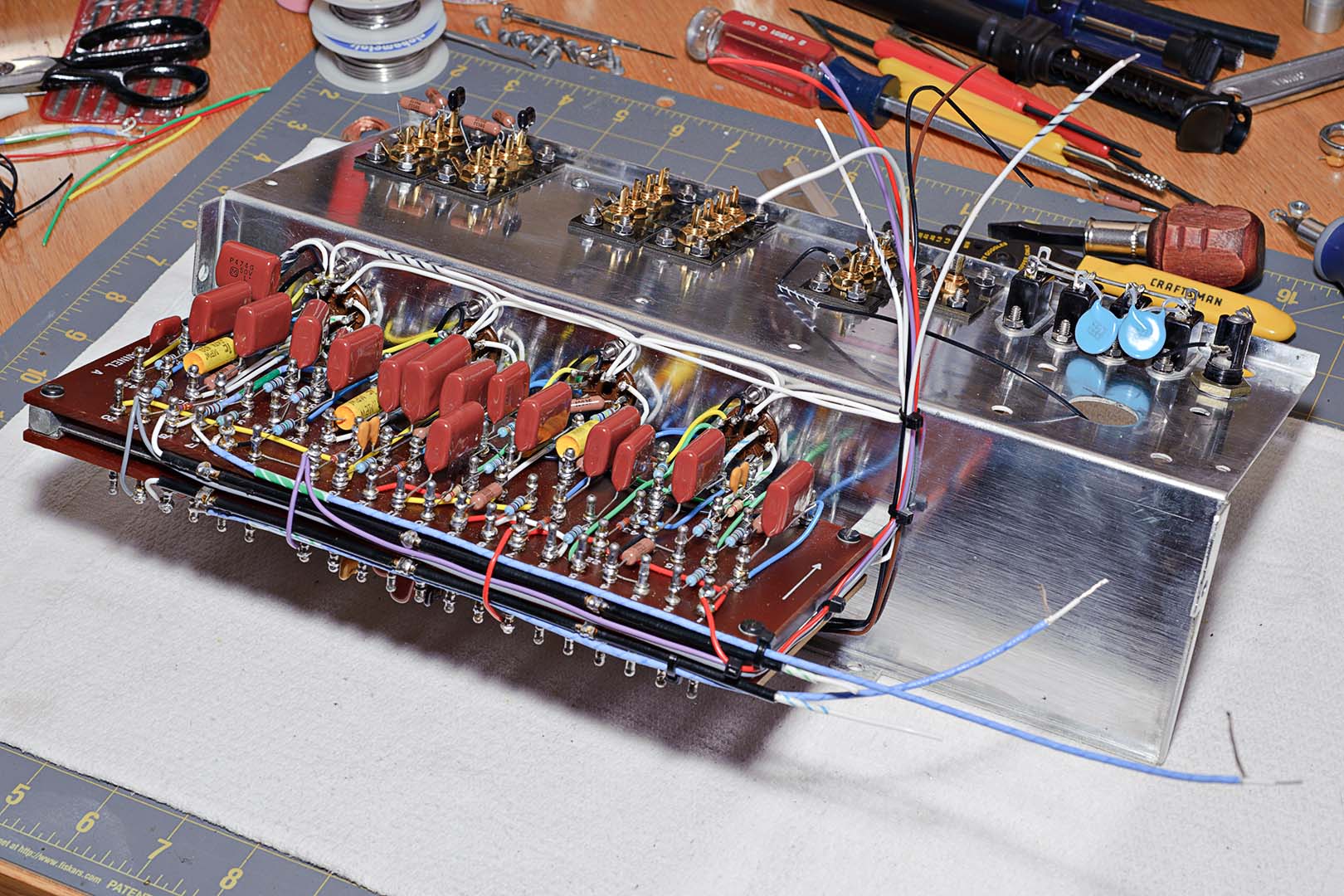

Shielded wire was prepared, attached to, and then run along the terminal board. Next, long lengths of purple, gray, and red wire were attached and dressed along the outside of the boards. These wires were then dressed together with the black, white, white/black, and brown wires from the early tube socket wiring described in yesterday's post. I'll make a note here that I am not using black tape to neatly bundle wires in my project. Instead, keeping up with modern technology, small black cable ties are being used whenever black tape is called out in the instructions.

Short lengths of the same purple, gray, and red colors were used to connect lugs between the A and B boards. Long lengths of wire were then prepped and run through the flexible black tubing.

That's it. I'm now on the top of page 23 and will stop for the night. The next section of the manual is to tackle the switch wiring. We're going to have to take another detour here from the instructions, but more on that in the next post.

As I end this posting, let's take a look at the work to this point. Here's a photo. It's beginning to look very nice, I think!

Total Time Spent: ~5 hours.

Subscribe to:

Post Comments (Atom)

So let's get into the Citation I refurb project. First, you need a unit to refurb. I happen to have a choice of 5 units to start with. Four were bought off eBay and I inherited my father's original Citation (more on that in some future posting). I am going to be replacing every electronic component in this system except the transformer and the choke. I will also be installing all new wiring and new RCA jacks. Therefore, I am mostly concerned with the cosmetic condition of the faceplate and knobs.

ReplyDeleteMy father's unit has a near mint faceplate although the knobs show a bit of oxidation. But since this is my first preamp refurb I'm not going to start with that unit. So I picked one of the eBay units, which actually has a very nice faceplate and very nice knobs as well. I may have to use these knobs on my dad's unit when I get to that project. Below is a photo of the front of the preamp that I will be refurbishing.

So let's open it up and see how it looks on the inside. Above is a top view photo of the unit with the cover removed. Hmmm... someone's already been at this unit. It looks like the unit has already undergone a line and phono section coupling cap replacement. The large blue objects are WIMA 0.1 uF caps. The white caps are Sprague and the yellow caps are a mix of WonderCaps and something labeled CDE. A look at the underside of the unit shows that terminal board A has the exact same brands in the same locations. So whoever did the work was using some amount of care.

None of the ceramic disc caps have been replaced. The power supply section also looks untouched from original.

It looks like all the resistors are original but there is some new Mogami single conductor shielded wire being run to the RCA jacks. In addition, it appears that the Stereo Reverse and Inverse Phase switches have been taken out of the circuit by simply cutting the shielded wires that lead to the switch.

The transformer exterior looks fine cosmetically. Probably no need to repaint it, especially since it will sit inside the wood case when the project is completed. Three out of the four convenience AC outlets are chipped, with two actually exposing just a slight bit of metal. So for safety's sake we'll probably be replacing these although I have no plans to actually use them.